As you know an EV draws power from its battery pack. The catch with LAC is that its two massive lithium brine projects one in Argentina and the other in.

More Electric Cars Can Mean More Damage To Mining Communities

More Electric Cars Can Mean More Damage To Mining Communities

Some might not be very green.

Electric car battery mining. This article originally appeared on the website of the. Image courtesy Protect Thacker Pass. Once on the road the carbon dioxide emissions of EVs depends on the power-generation fuel used to.

That could reach 19 million this year as VW Stellantis NV and BMW AG map out plans for new models and higher output and Ford Motor Co. March 10 2021 - by Tara Lohan. One large international zinc company mines around 14m tonnes a year.

Demand for nickel and cobalt for batteries is expected to increase Pathe said but new mines arent likely to be greenlighted until nickel rises from todays prices of around US7 per pound. Materials needed to make the batteries for electric cars and other clean technology is driving interest in deep-seabed mining and scientists fear the cost to the ocean will be steep. This is the kind of landscape that lithium mining for electric car batteries might destroy.

Mining for electric car batteries hundreds of times better than petrol car emission cycles. And during the time an electric car is on the road these batteries require electricity that may or may not be sustainably sourced. The short answer is that a number of rare metals need to be dug out of the earth from various mines.

Oceans Clean Water. As countries the world over legislate to phase out petrol and diesel cars attention is turning to the environmental impact of mining the materials needed for electric vehicle batteries. Lithium Americas is a Canadian lithium mining company.

A new study did a deep dive into the emissions from the full life cycles from petroleum. It is thought around 600000 tonnes of zinc would be required to make batteries for a million electric vehicles. A race is on to produce lithium in the United States but competing projects are taking very different approaches to extracting the vital raw material.

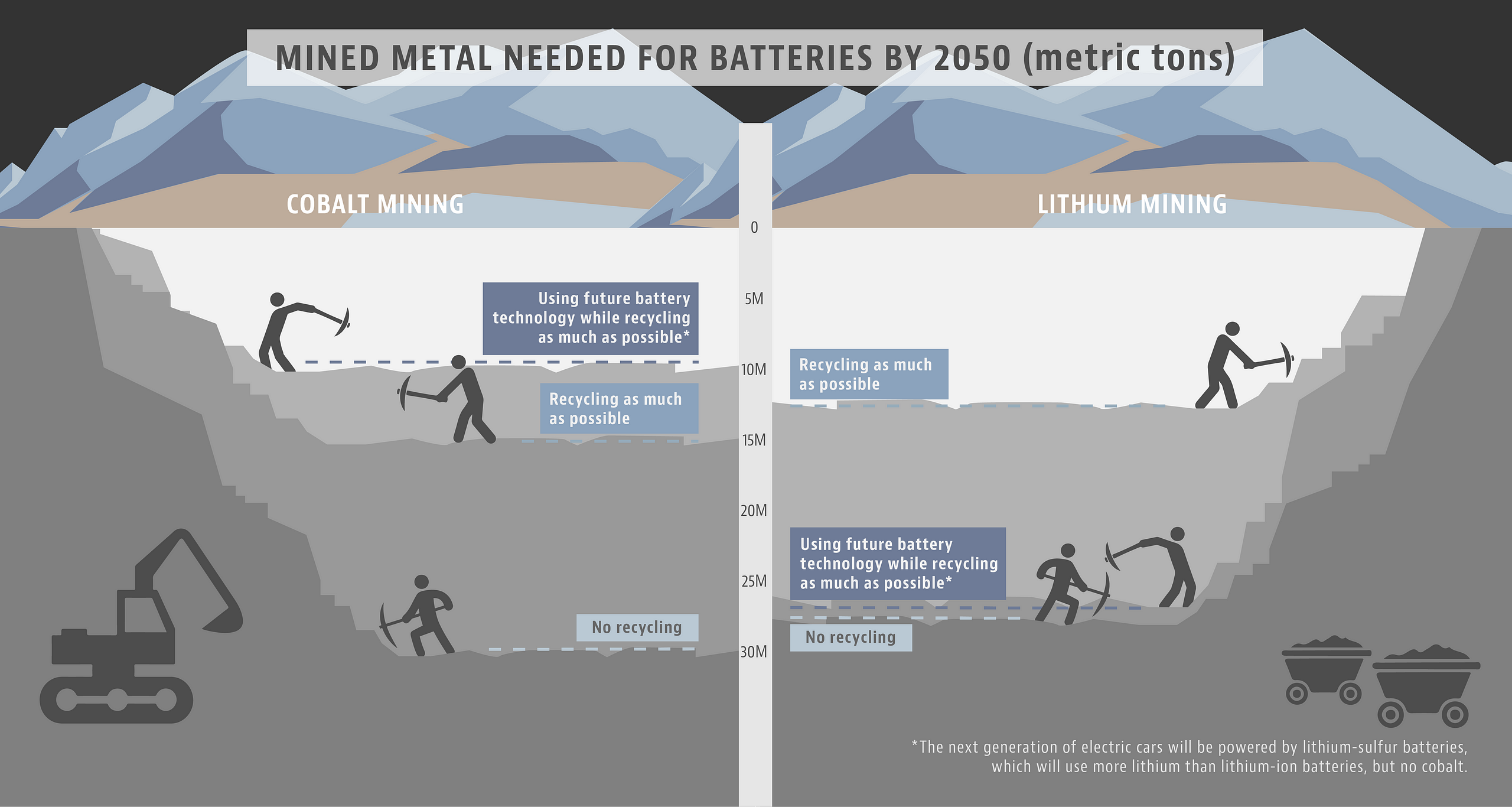

The Battery Mining Catch-22 Threatening The EV Revolution Electric vehicles need batteries and it takes one or two years to get a battery production plant up and running. After reading that recycling electric car batteries could reduce mining of metals by up to 55 you might be interested that researchers at Penn State found that lithium-iron-phosphate batteries could be cheaper and safer than the ones currently used. British scientists have also found a way to produce lithium for EV batteries in the UK.

On Tuesday KoBold Metals a mining exploration startup based out of the San Francisco Bay Area. These are then packaged into small individual battery cells alongside other materials such as plastic aluminum and steel before themselves being packed into battery modules. EV batteries are larger and heavier than those in regular cars and are made up of several hundred individual lithium-ion cells all of which need dismantling.

The Hidden Environmental Cost of EVs. A solder stands next to an electric car that uses cobalt batteries seen parked at a mining conference in the Democratic Republic of Congo last year Alamy. Monty Rakusen Getty Images.

These batteries are made of relatively rare metals and minerals which are often sourced using environmentally-invasive mining techniques. Environmentalists take aim at the mining projects required to obtain the lithium and other minerals required to build electric car batteries. And Volvo Cars commit to going almost all-electric.

So how exactly are these lithium-ion batteries for electric cars made. If electric cars are to work we need lithium lots of it 42 times more than we produce today but buckwheat found in. The equivalent amount for manufacturing a conventional car is 14000 pounds.

Scientists testing lithium car battery with electric motor car in battery research facility.